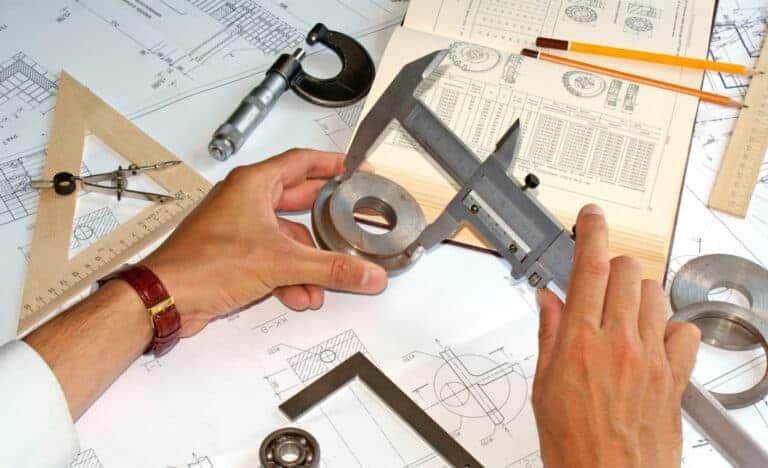

Dimensional Measurement Tools – Basics

This class is an introduction to some of the most common gages used on the shop floor. The purpose is to provide practical instruction on the different tools available and their proper use to build workers’ skill and knowledge.

Dimensional Measurement Tools – Basics

Basic Dimensional Measurement Tools and Methods builds a solid foundation of skills that workers can use across a broad spectrum of applications. It forms the basis for mastering more advanced measuring tasks to ensure that you’ll get the most accurate measurements possible. With this program, workers will master the essentials of handling, applying and reading the most common gages on today’s shop floors from steel rules to micrometers and height gages.

Course Objectives

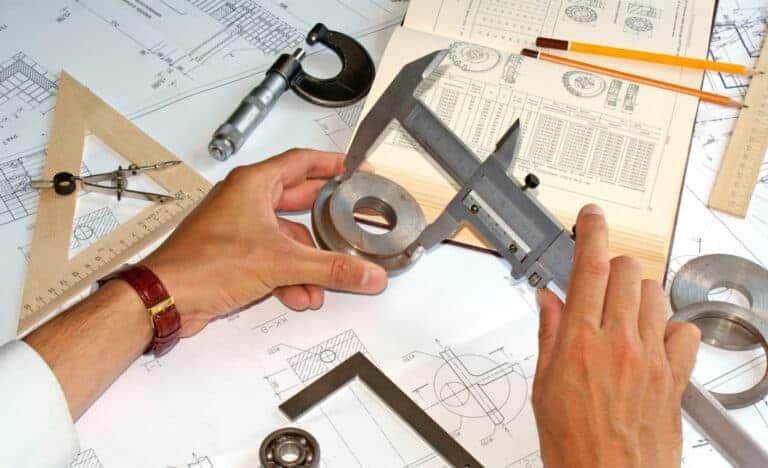

- Review fundamental dimensional measurement tools and methods

- Understand the use of variable gages, including steel rules, depth gages, dial gages, micrometers, and calipers

- Learn about attribute gages, such as plug, ring, and screw thread gages

- Develop practical skills in using various measurement tools

- Gain hands-on experience with both variable and attribute gages

Target Audience

- Production Workers

- Machine Operators

- Quality Control

- Shipping and Receiving

Agenda

INTRODUCTION

- Introduction and Key Concepts

- Variable and Attribute Measurements

- Other Types of Measurements

- 10:1 Rule

- Temperature, Uncertainty, Unnecessary Accuracy

- Gage Correlation

- Gage Maintenance, Handling and Storage and Tool Care

- Gage Selection Chart

- Fundamentals and Linear Tools

- Key terms and concepts

- Criteria for accurate measurements

- Rules – steel, hook, bevel protractor, basic depth gages

- Use of depth gages, inside and outside calipers, dial calipers and electronic calipers

- Micrometers and Dial Indicators

- Outside, inside, vernier and electronic micrometers

- Types of dial indicators

- Dial indicating gages – calipers, depth gages

- Fixed Gages

- Snap gages

- Plug gages

- Ring gages

- Screw thread plug gages

- Thread ring gages

- Surface Plate Equipment

- Surface plate equipment

- Gage blocks

- Height gages – vernier, dial, electronic

- Micrometer height gages

- Surface plate accessories

- Miscellaneous Equipment

- Surface Roughness Testers

- Shape and Profile Measurement

- Laser Designed Gaging

- Optical Comparators

Course Delivery

- In-Person Training

- Training for Teams

Prerequisites

- None

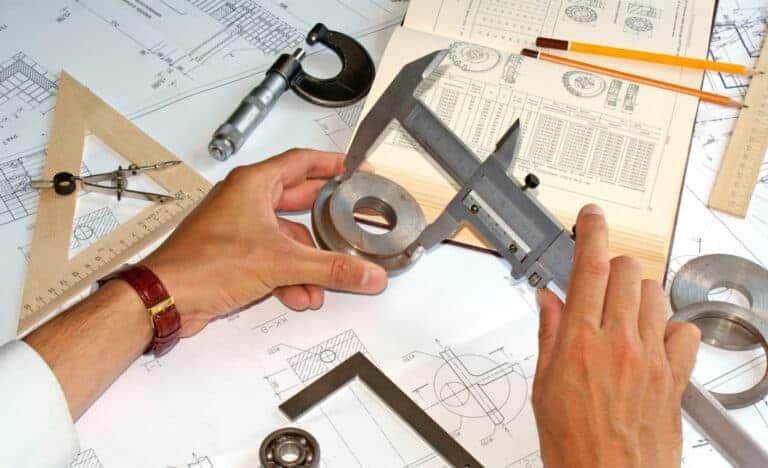

Upcoming In-Person Training For This Course

Dimensional Measurement Tools – Basics

Date: February 10-11

Location: Fox Valley Metrology

3114 Medalist Drive

Oshkosh, WI 54902

Limited to 8 Participants