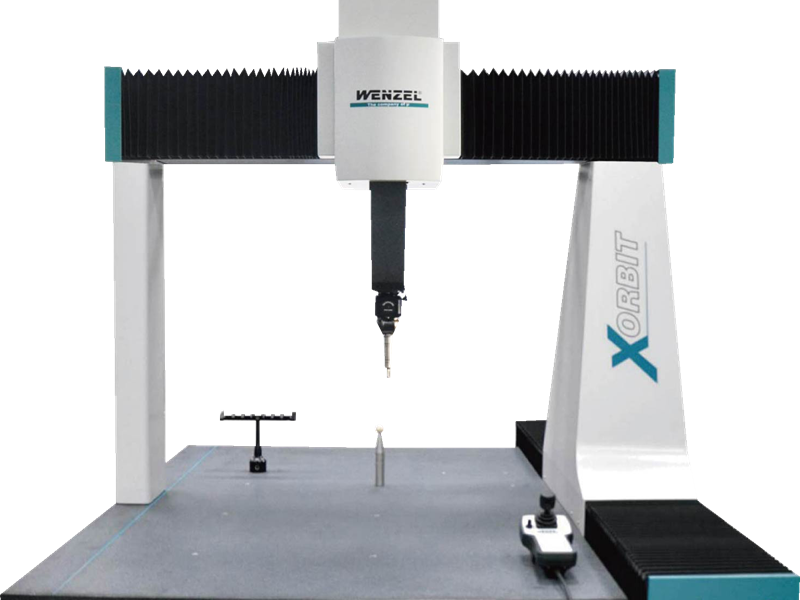

Wenzel XOplus 55 Coordinate Measuring Machine

Price: Contact Us

Retail Price: N/A

Your Savings: N/A

The XOplus Coordinate Measuring Machine is a mid-range CMM which bridges the technical and commercial gap between the German-built, premium LH systems and the popular XO CMM.

The XOplus brings the renowned stability of a granite CMM and high accuracy at a competitive price. The XOplus also has size ranges that are different to XO and LHG. The XOplus has bridge size of 55 (500mm by 500mm), 77 and 98 and each bridge sizes has different Y-axis lengths to suit customer needs. The XOplus has a particularly small footprint making it ideal for shops where real estate cost is at a premium.

- The Y-axis guide -way is machined directly into the base plate, providing optimal long-term stability

- Pre-stressed, encompassing air bearings in all axes

- Passive vibration dampers

- Active pneumatic vibration damping optionally available and field retrofittable

- Compact control panel with central, logarithmic joystick, "mouse function" and context-sensitive function buttons.

- Selectable joystick axis assignment

- The X-and Y-guide-ways feature bellows protections against contamination

- High-speed-dynamic servo drives with position monitoring combined friction power transmission

- Three-axis contouring controller with intelligent “look-ahead” function for application-optimised trajectory

- Manual temperature compensation (Automatic temperature compensation on all axes and work piece optionally available)

- Two-stage speed selection and variable speed adjustment (override 0-100%) in all operation modes, resulting insensitive movement via joystick or in CNC mode

- A motorised indexing head that mounts and re-orientates the probe repeatably to any one of 720 positions at 7.5° increments

- PH20 brings 5-axis measurement capability to touch-trigger applications on all sizes of CMM

- The revolutionary 5-axis probe system provides an extremely fast scanning speed solution with a high degree of measurement flexibility, and thus an extremely high throughput.

- Compact, module changing touch-trigger probe, which allows the use of a range of stylus configurations and extensions to access features on complex parts.

- Compact, module changing touch trigger probe particularly suitable for measuring tasks with tight dimensional tolerances for 3D free-form surfaces with longer styli.

- The most compact and versatile probe system for scanning on a global scale.

-

Passive probe, equipped with a high-resolution digital length measuring system (0.02 μm), which ensures outstanding measuring precision even when using long stylus inserts (up to 500 mm).

-

The 3D Line Scanner changes your coordinate measuring machine into the ideal machine to record and handle point clouds. Perfect for all who need to record and work on surfaces and outlines of physical objects.

- Unique, user-friendly UI

- 3D CAD Import – IGES, STEP & DXF

- Catia, SolidWorks, ProE, Parasolids & Unigraphics optional modules

- Inspection program creation from CAD model

- CMM and Renishaw probe simulation

- Object based programming

- Automatic routines

- Many reporting options

- Intuitive UI, consistent with Microsoft Windows

- 3D CAD Import – IGES, STEP, VDA-FS, Parasolid, ACIS & DXF

- Inspection program creation from CAD model

- Simulation, Verification & Optimization

- Object based automatic measuring

- Automatic routines

- Support for CT and optical scanners

- Many reporting options

Measurement Ranges, Weights

- X-Axis Measurement Range: 500mm

- Y-Axis Measurement Range: 500mm, 700mm or 1000mm (Additional Y ranges available upon request)

- Z-Axis Measurement Range: 500mm

- Useable Table Surface: 750mm x 1200mm, 750mm x 1400mm or 750mm x 1700mm,

- Machine Weight: 980 kg, 1140 kg or 1260 kg

- Permissible Part Weight: 200 kg or 300 kg

General Requirements

- Electric: Single-phase AC, 1 P+N+PE, 115/230 V ± 10 %, 50/60 Hz, max. 1000 VA, ace. to EN 60204/1

- Compressed Air: Supply pressure 6-10 bar, pre-filtered, quality according to ISO 8573-1 : Class 4 or better

- Air Consumption: Min. 70 NI/min, higher consumption possible, depending on application (pneumatic dampers)

Measuring Accuracy

- Measurement System: Photoelectric scale system, Optical division 20 µm

- Resolution: 0.1 µm

- Probing Uncertainty (TP200 Head): 1.8 µm

- Probing Uncertainty (SP25 Head): 1.6 µm

- Volumetric Length Measuring Uncertainty (TP200 Head): 1.8 µm + L/350

- Volumetric Length Measuring Uncertainty (SP25 Head): 1.6 µm + L/350

- Volumetric Scanning Probing Uncertainty (SP25 Head): 2.2 µm

- Total Measuring Time for THP: 68 seconds

Operating Environment

- Operating Temperature: 15-30ºC

- Temperature Range for MPEE: 18-22ºC

- Relative Humidity: 40-70%

Dynamics

- Joystick Operation: 0-20 mm/s (Creep Mode), 0-100 (Normal)

- CNC-Mode Vmax: 300 mm/s (Axial), 520 mm/s (Volumetric)

- CNC-Mode Amax: 1200 mm/s2 (Axis-Related), 2000 mm/s2 (Volumetric)

Overall Dimensions

- Width: 1135mm

- Length: 1390mm, 1590mm or 1920mm

- Height: 2505 mm

What applications are suitable for the XOplus CMM?

Applications include machined components, stampings, tooling, and turbine blades.

What are some other Features/Benefits of the XOplus CMM?

- Excellent price/performance ratio

- Renishaw Probe Systems let you add sensor technology as your needs change and grow.

- Drive systems and air bearings arrangements like high-end continuous industrial scanning CMMs.

If your inspection process calls for a coordinate measuring machine that can do more than just tactile touch probing, but you still need high value, you don’t have to sacrifice the intrinsic accuracy of granite. Our newest XOplus coordinate measuring machine is built with thermally stable granite structures and fills the gap between premium machines and the Xorbit workhorse coordinate measuring machine.